GERMOS - SMOKE GENERATORS

GERMOS Vapour-Smoke Generator

NESS Friction Smoke Generator

NESS Sawdust Smoke Generator

NESS Liquid Smoke Generator

Metalquimia - STUFFERS

TWINVAC SIGNATURE 4.0

TWINVAC EVOLUTION

TWINVAC PC CLASSIC

TWINVAC HP CLASSIC

CARRUSEL VACUCLIP - 2

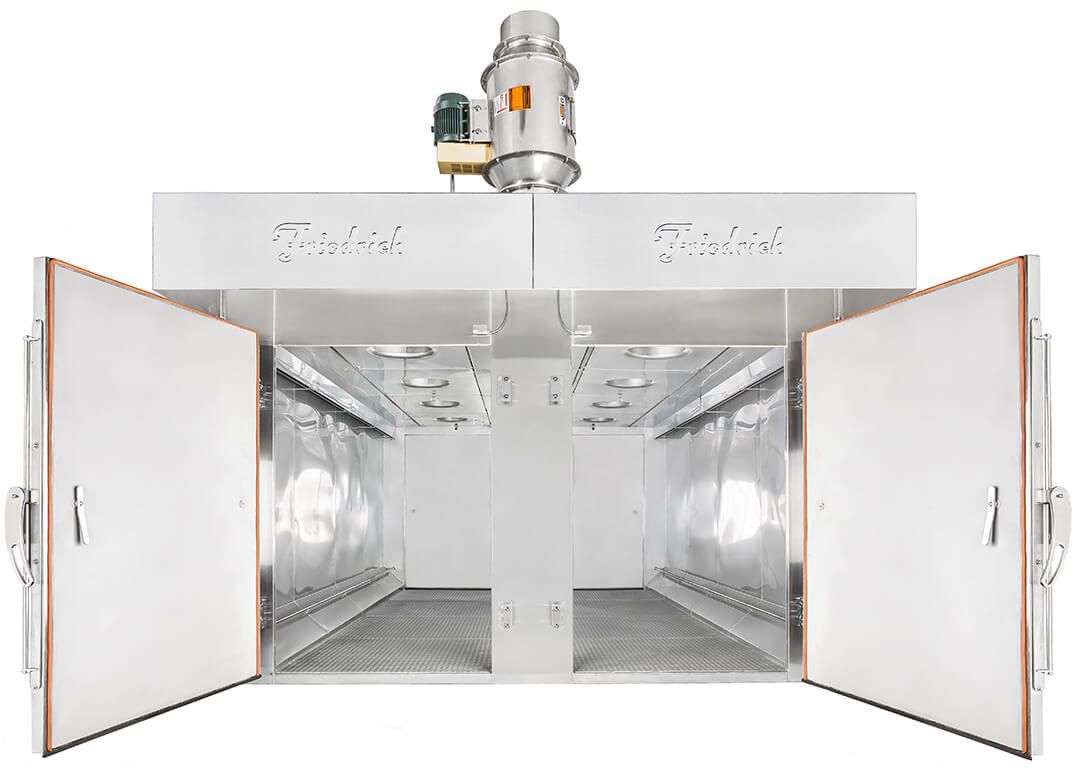

Friedrich - SMOKEHOUSE

FRIEDRICH SMOKEHOUSE

Friedrich - SMOKE GENERATOR

Friedrich NS-90 Smoke Generator

Friedrich NS-80 Smoke Generator

Metalquimia - D-ICING

D-ICER DEFROSTING DRUMS

FROZEN BLOCK PRESSES - D-BREAKER

Metalquimia - QDS Process

QDS-PROCESS

QDS SNACKS

Friedrich - ROASTERS & SMOKERS

Max Flavor 400 Roaster

CT-60 Roaster/Smoker

Friedrich - BLAST CHILLERS

BLAST CHILLER

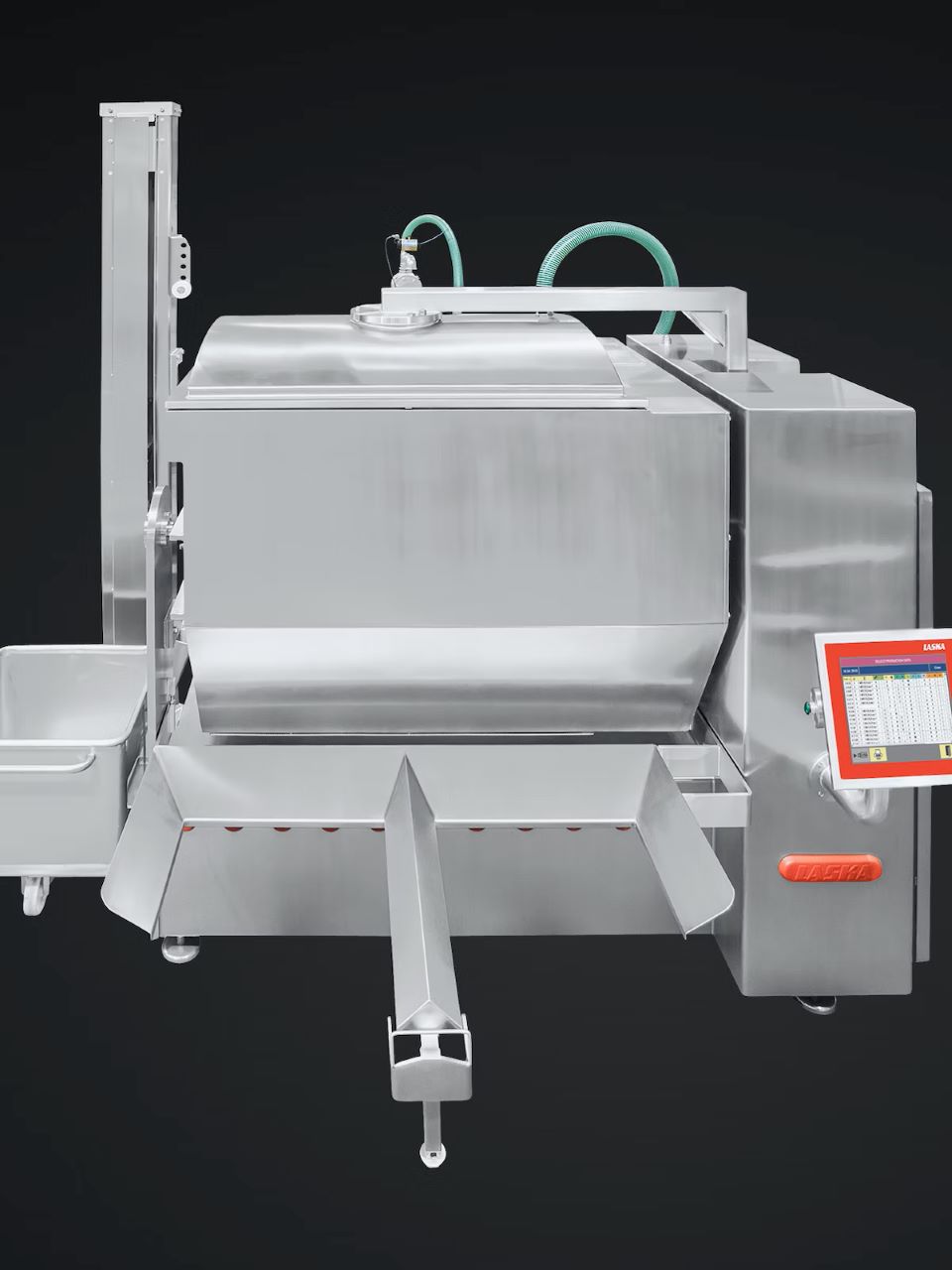

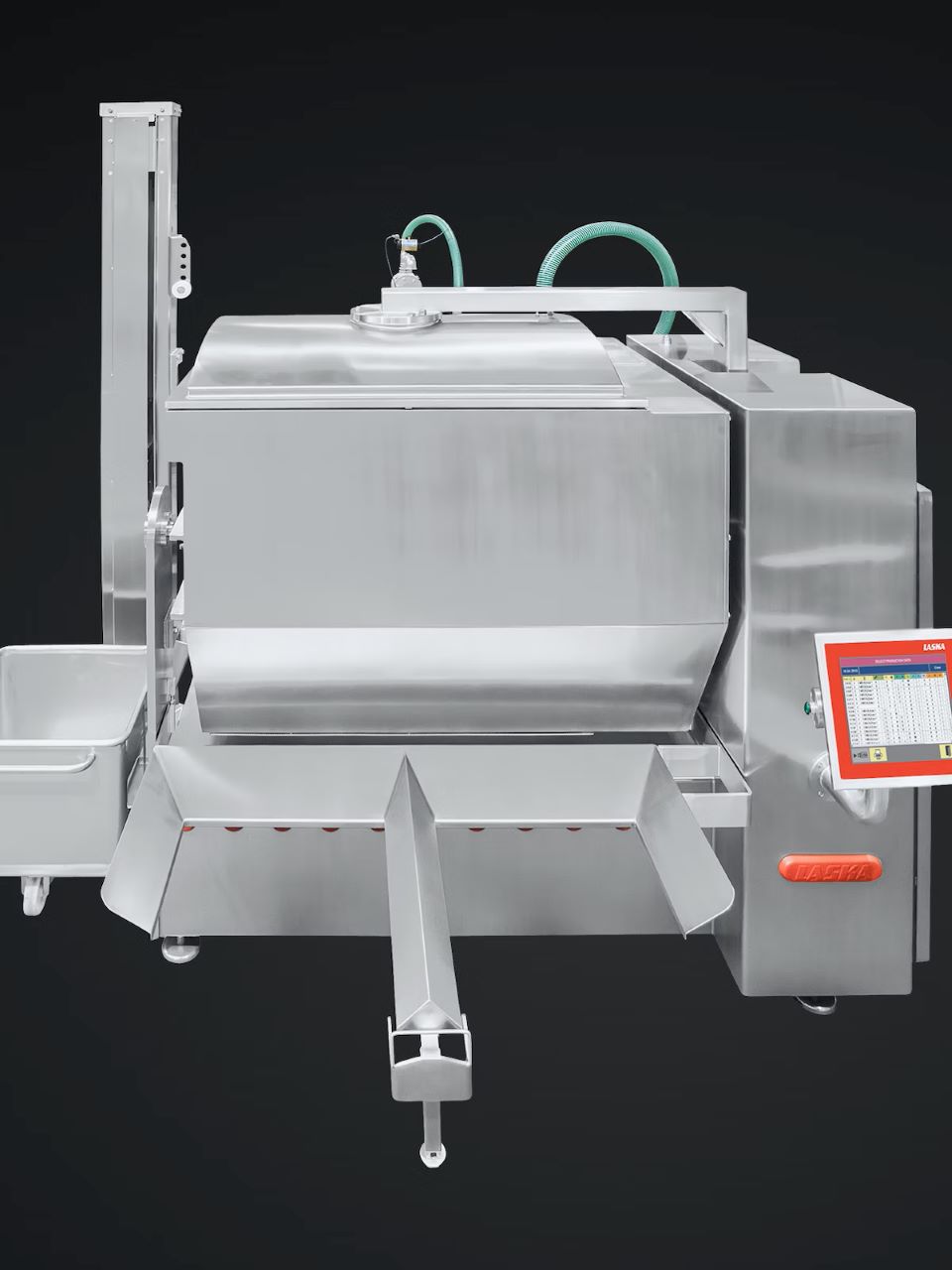

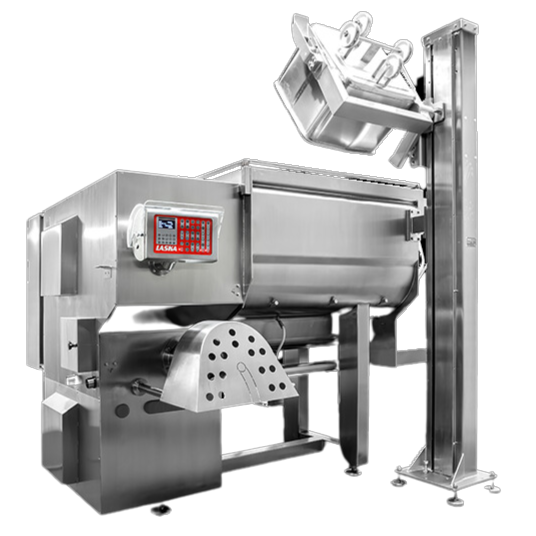

Laska - MIXERS

.jpg)

ME 130 N

Hopper capacity - 130 l

Max. mixing capacity - 110 kg

Draining - tilting

.png)

ME 250 N

Hopper capacity - 250 l

Max. mixing capacity - 200 kg

Draining - tilting

.png)

ME 500 N

Hopper capacity - 500 l

Max. mixing capacity - 400 kg

Draining - tilting

.jpg)

ME 1000 N

Hopper capacity - 1000 l

Max. mixing capacity - 800 kg

Draining - tilting

ME 1000

Hopper capacity - 1000 l

Max. mixing capacity - 800 kg

Draining - Side flap

.jpg)

ME 1500

Hopper capacity - 1500 l

Max. mixing capacity - 1200 kg

Draining - Side flap

.jpeg)

ME 2000

Hopper capacity - 2000 l

Max. mixing capacity - 1600 kg

Draining - Side flap

.jpg)

ME 3000

Hopper capacity - 3000 l

Max. mixing capacity - 2400 kg

Draining - Side flap

.png)

ME 3000-H

Hopper capacity - 3000 l

Max. mixing capacity - 2400 kg

Draining - Two side flaps

.png)

ME 4500

Hopper capacity - 4500 l

Max. mixing capacity - 3600 kg

Draining - Side flap

Laska - FROZEN MEAT CUTTERS

GS 510

Block cross-section - 500 x 300 mm

Processing temperature - > -15°C

Max. throughput - 4000 kg/h

GFS 620

Block cross-section - 600 x 380 mm

Processing temperature - > -20°C

Max. throughput - 10000 kg/h

.png)

G 530

Block cross-section - 520 x 300 mm

Processing temperature - > -25 °C

Max. throughput - 5000 kg/h

.png)

G 740

Block cross-section - 700 x 400 mm

Processing temperature - > -25 °C

Max. throughput - 12000 kg/h

REX-Technologie - LINK CUTTER

.jpg)

RSS 70

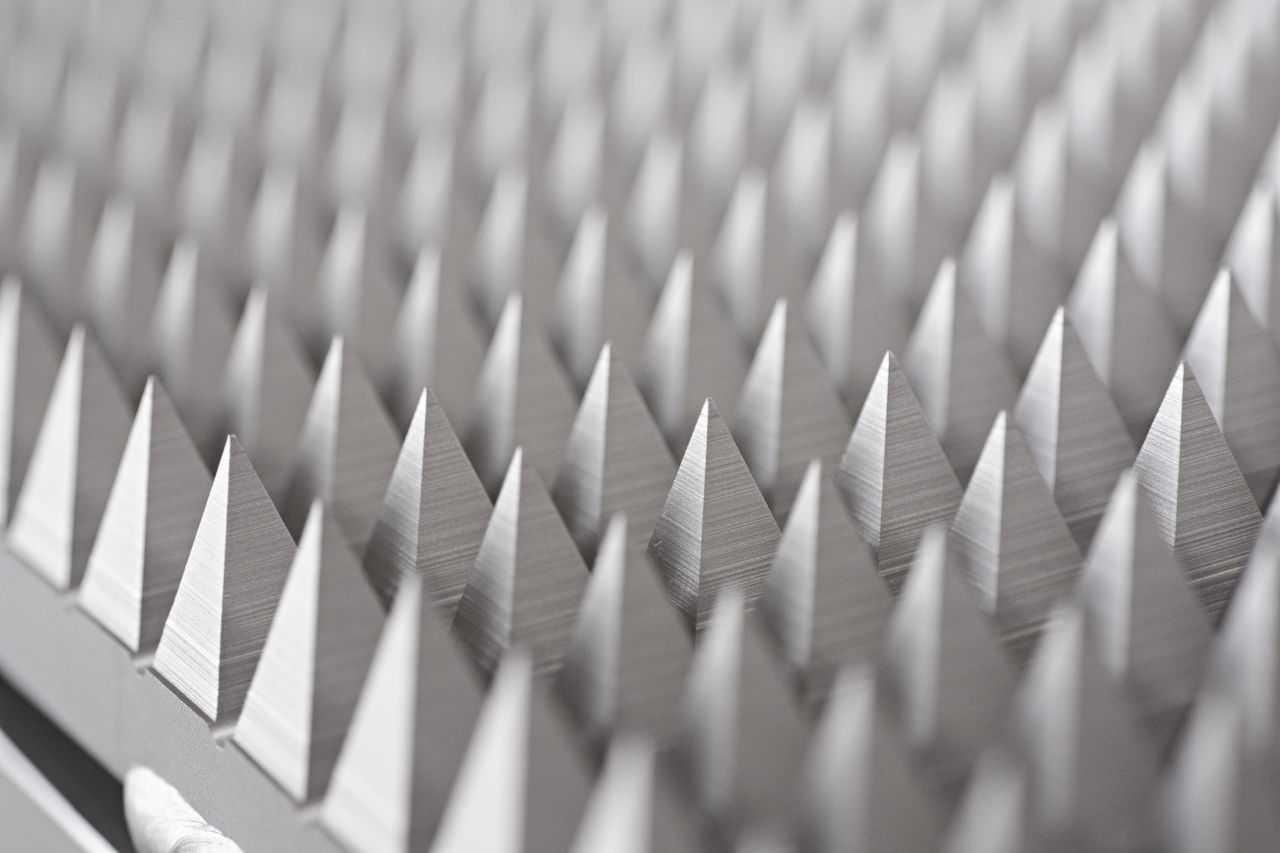

Laska - BOWL CUTTERS

The cutting effect of the LASKA cutter has been continuously improved in the past few years by optimizing speed, the shape of the knives and the cutting chamber. This has had a special impact on the stability of the sausage meat, on machine cleaning and on cutting set maintenance. Featuring high cutting rates and a special cutting geometry, the LASKA cutter ensures a consistently smooth and cohesive product in a short time.

.jpg)

BOWL CUTTER - K 60/65-B

Model Specifications:

- Bowl capacity: 60l/65l

- Blade shaft speed: 5100 rpm

- Cutting speed:100 m/s

.jpg)

BOWL CUTTER - K 130-B

MODEL SPECIFICATIONS:

- Bowl capacity: 130l

- Blade shaft speed: 4700 rpm

- Cutting speed: 120 m/s

Bowl Cutter - KCU 200

MODEL SPECIFICATIONS:

- Bowl capacity: 200 l

- Blade shaft speed: 4600 rpm

- Cutting speed: 128 m/s

Bowl Cutter - K 200-B

MODEL SPECIFICATIONS:

- Bowl capacity: 200 l

- Blade shaft speed: 5800 rpm

- Cutting speed: 160 m/s

BOWL CUTTER - K 330-B

MODEL SPECIFICATIONS:

- Bowl capacity: 330 l

- Blade shaft speed: 4800 rpm

- Cutting speed: 160 m/s

BOWL CUTTER - K 500-B

MODEL SPECIFICATIONS:

- Bowl capacity: 500 l

- Blade shaft speed: 4200 rpm

- Cutting speed: 160 m/s

BOWL CUTTER - K 750-B

MODEL SPECIFICATIONS:

- Bowl capacity: 750 l

- Blade shaft speed: 3300 rpm

- Cutting speed: 160 m/s

GERMOS - SMOKING UNITS

SMOKING UNITS - Hot or Cold Smoke

GERMOS - COOKING HOUSES

COOKING HOUSES

Laska - EMULSIFIERS

LASKA'S patented cutting concept for their emulsifiers supplies maximum quality at very high output per hour. Their one-of-a-kind automatic cutting-tool adjustment also minimizes wear, considerably cutting cost of operation.

FZ 175

Perforated disk Ø - 175 mm

Cutting blade speed - 3600 rpm

Maximum throughput rate - 5.500 kg/h

FZ 225-H

Perforated disk Ø - 225 mm

Cutting blade speed - 3600 rpm

Maximum throughput rate - 12.000 kg/h

Laska - MIXER-GRINDERS

LASKA mixer-grinders combine the functions of a mixer and grinder. Different blade sets produce finest cutting sizes from fresh as well as frozen material and intermeshing helical paddle shafts ensure perfect mixing.

WMW 1330

- Perforated disk Ø 130 mm

- Hopper capacity 380 l

- Max. mixing quantity 300 kg

WMW 1680

- Perforated disk Ø 160 mm

- Hopper capacity 800 l

- Max. mixing quantity 650 kg

WMW 2080

- Perforated disk Ø 200 mm

- Hopper capacity 800 l

- Max. mixing quantity 650 kg

WMW 2012

- Perforated disk Ø 200 mm

- Hopper capacity 1200 l

- Max. mixing quantity 1000 kg

WMW 2020

- Perforated disk Ø 200 mm

- Hopper capacity 2000 l

- Max. mixing quantity 1600 kg

Nu-Clean Sanitary Conveyor Systems - SANITARY CONVEYOR SYSTEMS

Nu-Clean builds many special products for the food industry. Our three conveyor systems are The “Quantum” for sanitary direct food contact, Our “Atomic” for sanitary conveyors but with a devices, and the “Classic” our all stainless, bolt together, modular systems. The Classic is our Panel and Channel styles of construction. We also build many special systems such as Inspection rejection conveyors for metal detector, X-ray, and Checkweigher systems. Our AMI Sanitary Platforms are the benchmark in sanitary construction.

Laska - GRINDERS

- Easy handling and user-friendly, robust operating elements

- Easy and quick exchange of cutting act

- Low current consumption due to state-of-the-art drive and control technology

- Integral control cabinet ensures compact design as well as long service life of electrical components

- Minimum maintenance required due to field-tested machine concept

- Easily accessible inspection doors

- Worldwide service network and competent advice

- Cleaning ducts provided with special sealings to ensure hygienic cleaning

- Base plate prevents soiling of the machine interior

- Polished surfaces for highest possible hygienic standard

- Clearly arranged control system and high operating safety

- Compact and space-saving design with integral control cabinet

- Long service life

- Low operating noise

W130-H Filling Grinder

MODEL SPECIFICATIONS:

- Perforated disk: 130 mm

- Hopper capacity: 48 l

- Max. output / h: 2500 kg/h

WW130-H Angle Grinder

WW 160-H & WW 200-H ANGLE GRINDER

MODEL SPECIFICATIONS

WW 160-H

- Perforated disk Ø: 160 mm

- Hopper capacity: 385 l

- Max. output / h: 9100 kg/h

WW 200-H:

- Perforated disk Ø: 200 mm

- Hopper capacity: 385 Liter

- Max. output / h: 14000 kg/h

WWB 200-H & WWB 300-H Frozen Meat Super Grinder

MODEL SPECIFICATIONS

WWB 200-H:

- Perforated disk Ø: 200 mm

- Hopper capacity: 385 Liter

- Max. output / h: 14000 kg/h

WWB 300-H:

- Perforated disk Ø: 300 mm

- Hopper capacity: 800 Liter

- Max. output / h: 21000 kg/h

WWR 160-H

MODEL SPECIFICATIONS:

Perforated disk Ø: 160 mm

Hopper capacity: 580 l

Max. output / h: 9100 kg/h

WWR 200-H

MODEL SPECIFICATIONS:

Perforated disk Ø: 200 mm

Hopper capacity: 580 l

Max. output / h: 14000 kg/h

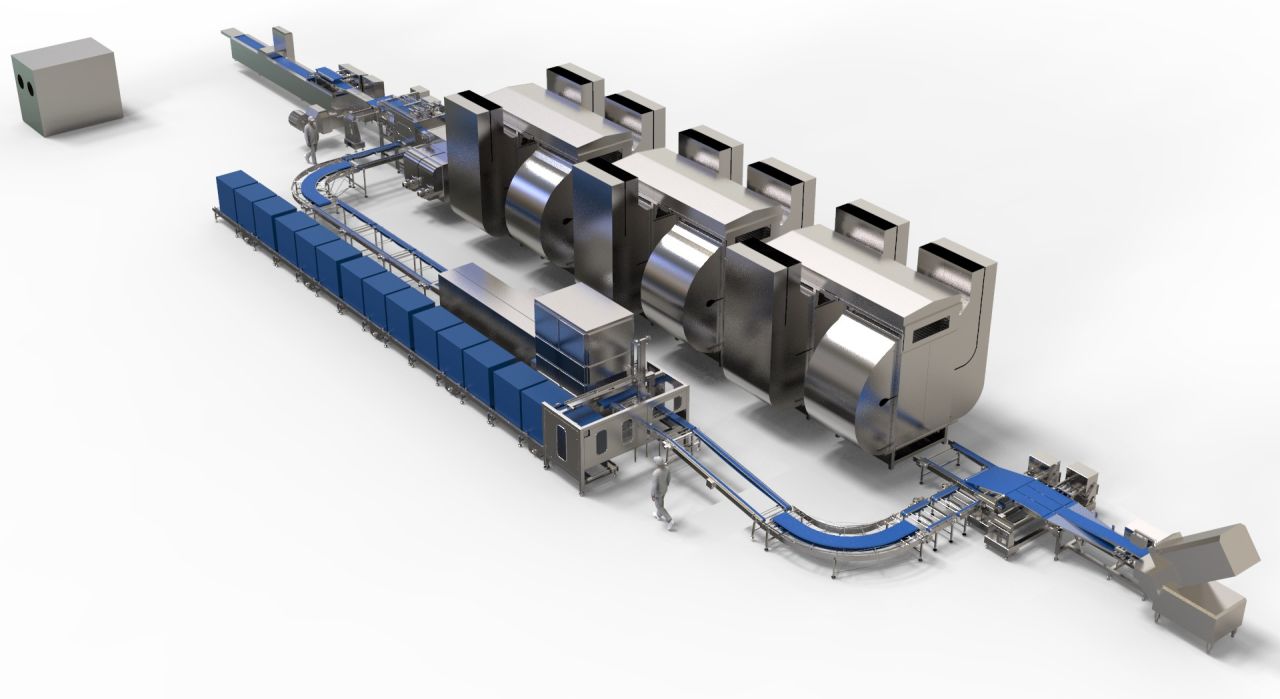

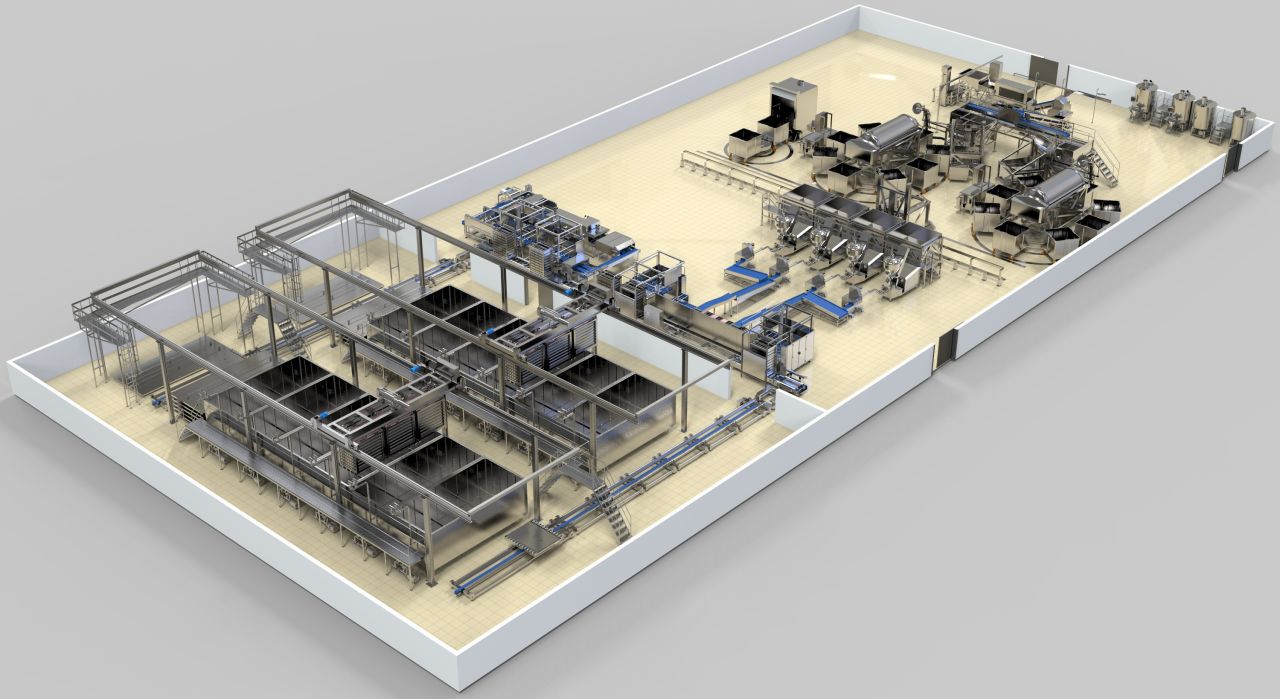

Metalquimia - 4.0 PLANTS

AUTOLINES 4.0

MODELS:

TWINLINE 4.0.

TWINLINE + COOKLINE 4.0.

SEMIAUTOMATIC LINES 4.0

MODELS:

BBV Line

Thermocomputer Line

PX LINES

MODELS:

PX Line

PX Line 1X Version

MQConnect

Metalquimia - TENDERIZER

.jpg)

MULTIBLADE

BLADETENDER

AUTOGRIND/FILOGRIND

ROLLERPRESS

BLADEHAMMER

TWINHAMMER

Metalquimia - COOKING

COOKLINE 4.0

Metalquimia - BRINE PREP

MOLISTICK 750

MODELS:

MOLISTICK-750

MOLISTICK-750 L

Metalquimia - VACUUM TUMBLERS

TURBOMEAT® 4.0 SIGNATURE

.jpg)

TURBOMEAT®

THERMOMAT

THERMOCOMPUTER

SMARTMIXER

Metalquimia - SAUSAGE EQUIPMENT

HD EVOLoader

Metalquimia - INJECTORS

AUVIPLUS SPRAY MARINATING

MULTIPLUS SPRAY MARINATING

BACON INJECTOR

MARINATOR MARINATING DRUMS

MOVISTICK CLASSIC INJECTORS

.jpg)

MOVISTICK TRIPLEX INJECTORS

MOVIPLUS 4.0 SIGNATURE EDITION

MOVIPLUS 4.0

.jpg)

INJECTION FILTERS & ACCESSORIES - DYNAMIC INJECT CONTROL

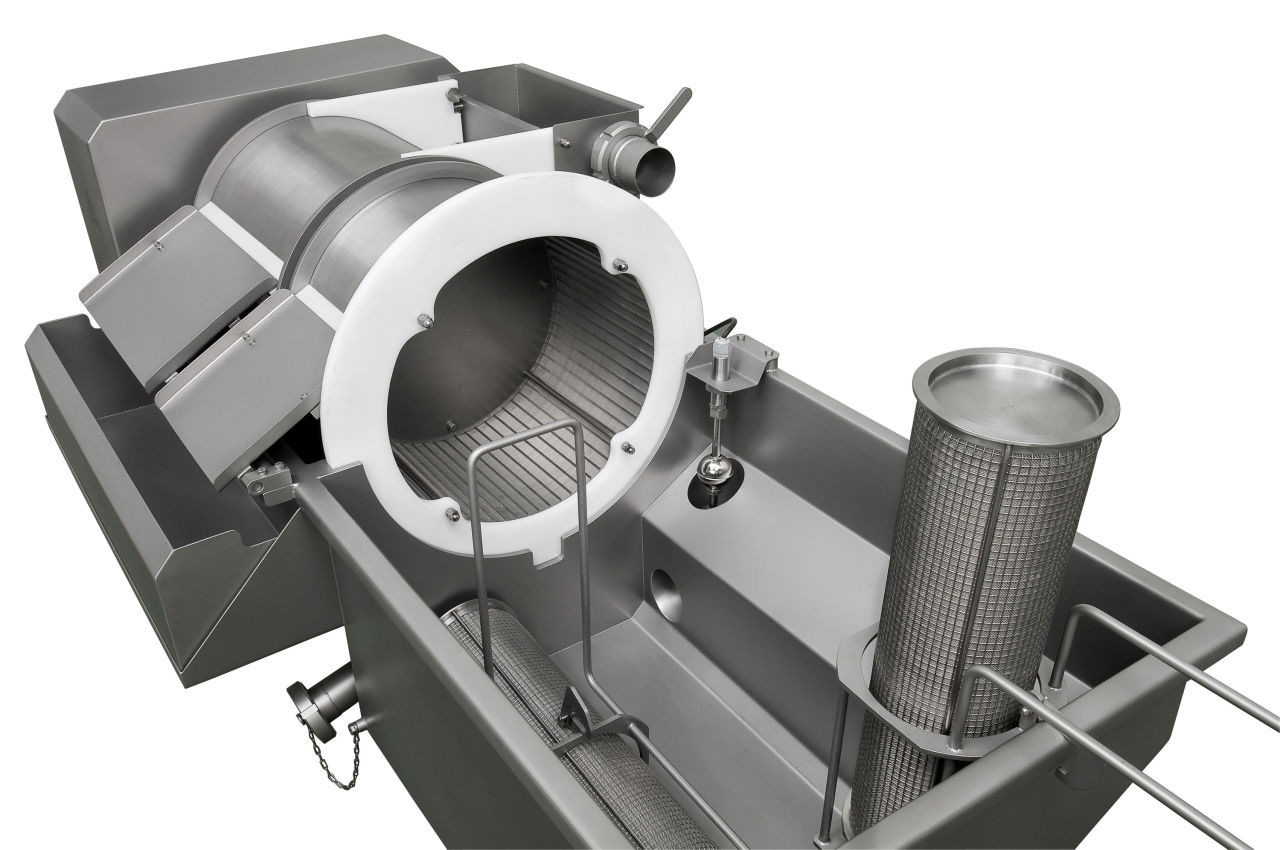

INJECTION FILTERS & ACCESSORIES - ROTARY FILTERS

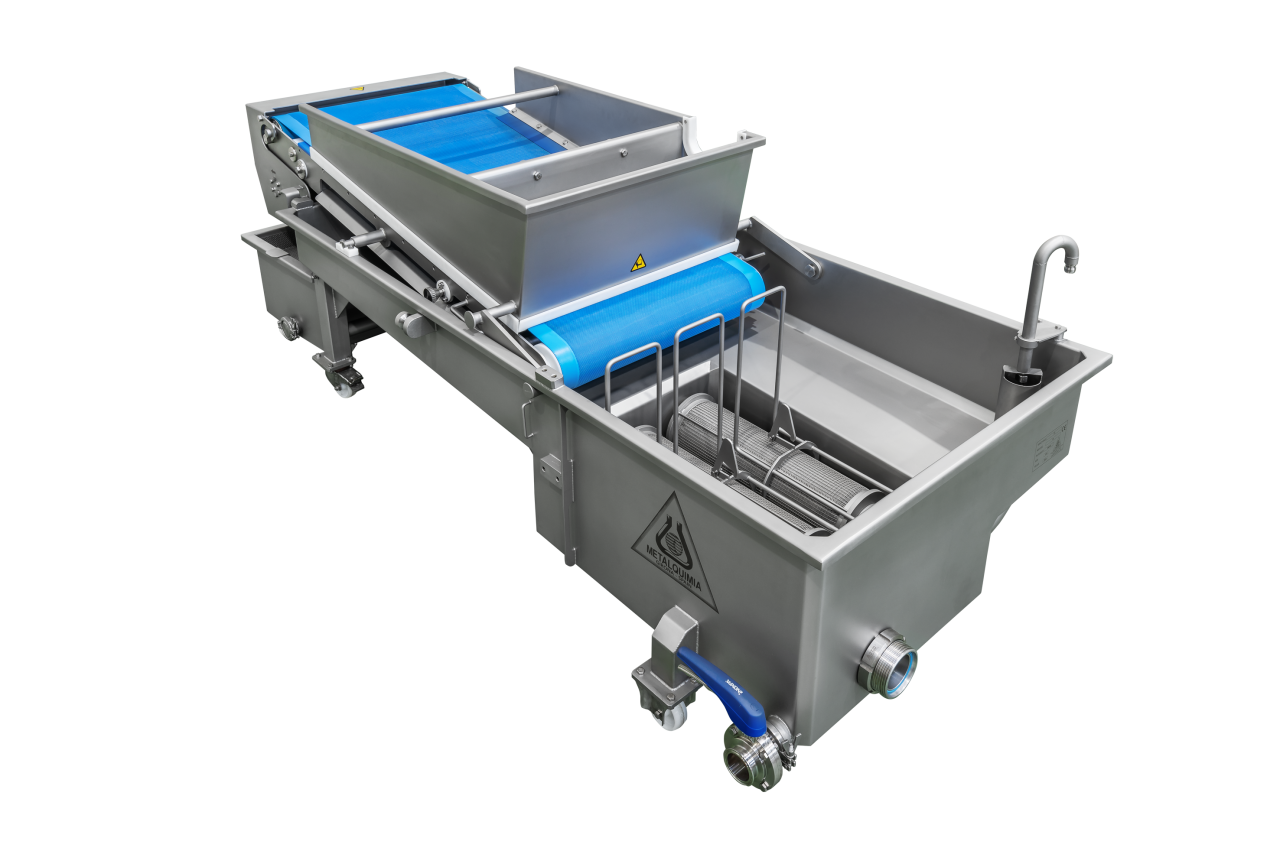

INJECTION FILTERS & ACCESSORIES - BELT FILTERS

MODEL:

BELT FILTER FB-34

.jpg)

INJECTION FILTERS & ACCESSORIES - INJECTIOMETER

.jpg)

INJECTION FILTERS & ACCESSORIES - NEEDLECLEAN

MOVIMAX ZERO

GERMOS - MATURING/ DRYING INSTALLATIONS

GERMOS maturing-/drying installations are designed according to the individual customer requirements. Our broad delivery spectrum offers our customers a choice between a wide variety of executions:

- Capacity of installation: 1 to 14 trolleys in one- or two-row execution

- Our brand UNIGAR: single air system

- Cur brand GERMOS: central air system

- Passing installations optionally

- Possible execution of doors: swing door with or without sight glass, lifting door

- Different types of coolants possible

All our installations are produced in our main plant are subject to the highest quality standards. We meet the regulations and standards of the food industry and use only high quality stainless steel (1.4301 up to 1.4571). When selecting our suppliers, we rely on regional and national goods. We strive for sustainability and short supply chains!

The system's availability is ensured by the robust construction. In case of a failure, we are available with our well-stocked range of spare parts. A fast delivery in case of need is secured. Over 80% of our spare parts orders are shipped within 24 hours.

All our installations are equipped with state-of-the-art control technology and documentation systems. The efficiency of the installation can be evaluated at any time using our Energy-Management-System as an option.

.jpg)

MATURING/ DRYING INSTALLATIONS

Menozzi Food Technology - AUTOMATIC DEMOULDING MACHINE

The DSA automatic demoulding machine is designed to satisfy industrial production needs. The simple and minimal mechanics combined with a new generation control software make this machine fast, reliable and versatile, with low costs and almost no maintenance requirements.

AUTOMATIC DEMOULDING MACHINE

Menozzi Food Technology - SHAPING PRESS

AUTOMATIC PRESS FOR SEASONED HAM IN RECTANGULAR OR TRADITIONAL SHAPE

SHAPING PRESS

GERMOS - COOKING KETTLES

The stable and self-supporting compact construction in stainless steel is completely watertight and available in two basic versions. The cooking kettle can be placed with a waterproof floor seal on an existing base. The second delivery execution is the version with kettle feet and a waterproof base plate.

Accessories such as cooking baskets and kettle floats of all sizes complete the equipment of our cooking kettles.

.jpg)

COOKING KETTLES

GERMOS - BAKING INSTALLATIONS

.jpg)

Baking Installation

GERMOS - COMPACT-CLIMATE UNIT - CCU

from room temperature up to 25°C

All parts are stainless steel. The Compact Climate Unit is delivered completely installed and the usage is very simple.

.jpg)

CLIMATE CONTROL UNIT (CCU)

Menozzi Food Technology - AUTOMATIC MOLD PRESS

AUTOMATIC MOULD PRESS

Menozzi Food Technology - BRINE MIXER

MM - LOW VISCOSITY BRINES

MM ATOM

Menozzi Food Technology - SEMIAUTOMATIC PRESS