Chilling product through the hot zone has become a priority for many processors and traditional cooling methods are being challenged. The solution is a blast chiller from Friedrich. We’ve combined high velocity air with a precise air flow system to minimize cooling time. Depending on the product, an intermittent shower can also be used to further speed the process.

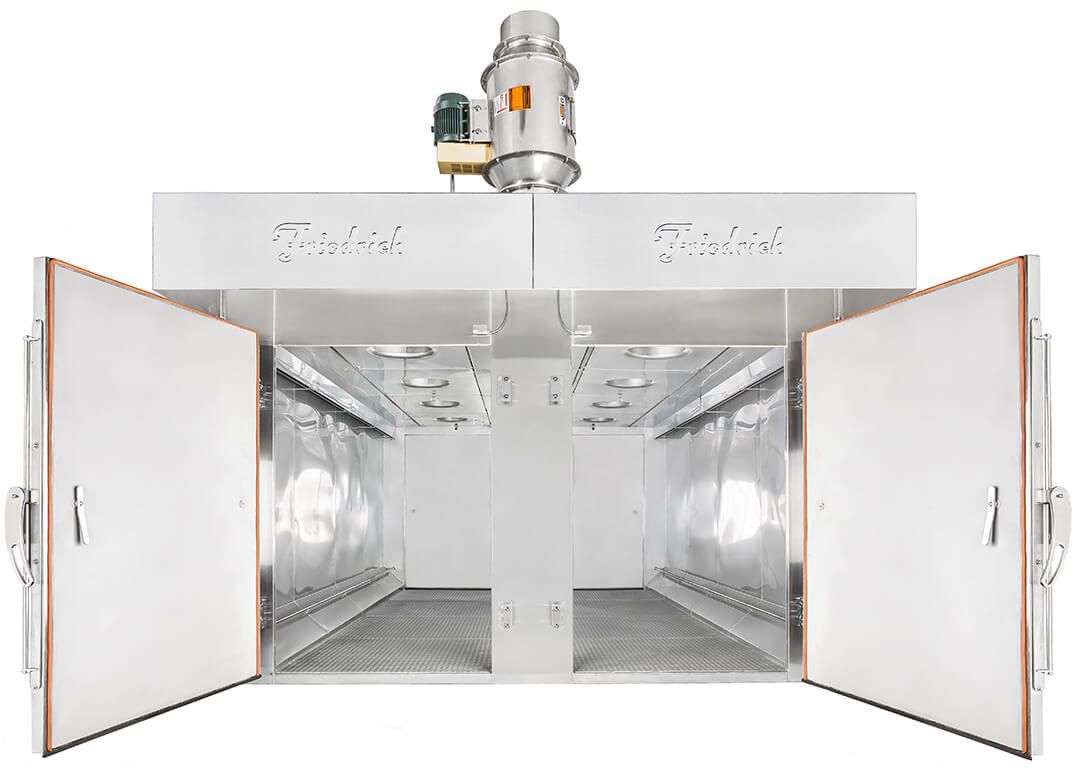

QUALITY IMPROVEMENT - The Friedrich blast chiller utilizes high velocity and precise air flow to speed up the chilling process and maximizes production capacities. The open design provides flexibility to chill a variety of product shapes and sizes.

LESS DEHYDRATION - Blast chilling immediately stops the moisture in food from evaporating, thereby preventing dehydration. The fragrance and flavor of foods is often linked to the right amount of moisture contained in the food.

INCREASE YIELD - By minimizing moisture loss the product flavor is maintained and at the same time the shelf-life is extended. The longer shelf life makes possible to increase production numbers.

REDUCTION in BACTERIAL GROWTH - Bacterial proliferation is very high when food is at a temperature of between +150˚F and +50˚F. Around +100˚F the number of bacteria doubles every 20 minutes.

The Friedrich blast chiller makes it possible to “cross” the range of hazardous temperatures quickly, taking the core of the food to +40˚F in approximately 90 minutes. This reduces the quantity of bacteria in food after cooking to a minimum, improving food quality, organoleptic properties and safety.

YOUR PRODUCT IS NOT COMPLETELY COOKED UNTIL IT HAS BEEN PROPERLY CHILLED. When it comes to producing a consistent product, chilling is just as important as cooking.

Details, Features and Benefits:

- Friedrich Blast Chillers provide rapid, uniform chilling of your product from the “hot zone” to 40°F

- Provides flexibility to chill a variety of product shapes and sizes

- High velocity air with precise air flow speeds up the chilling process and maximizes production capacities

- Minimizes moisture loss, improves flavor and yield, and extends product shelf- life

- Test your product in your plant with our self-contained test chiller

- Stainless steel construction

- Choice of coil materials

- Modular design for infinite configurations

- 5 HP motor per truck

- Control choice to fit your needs

Ask about our self-contained test unit; test your product in your plant.